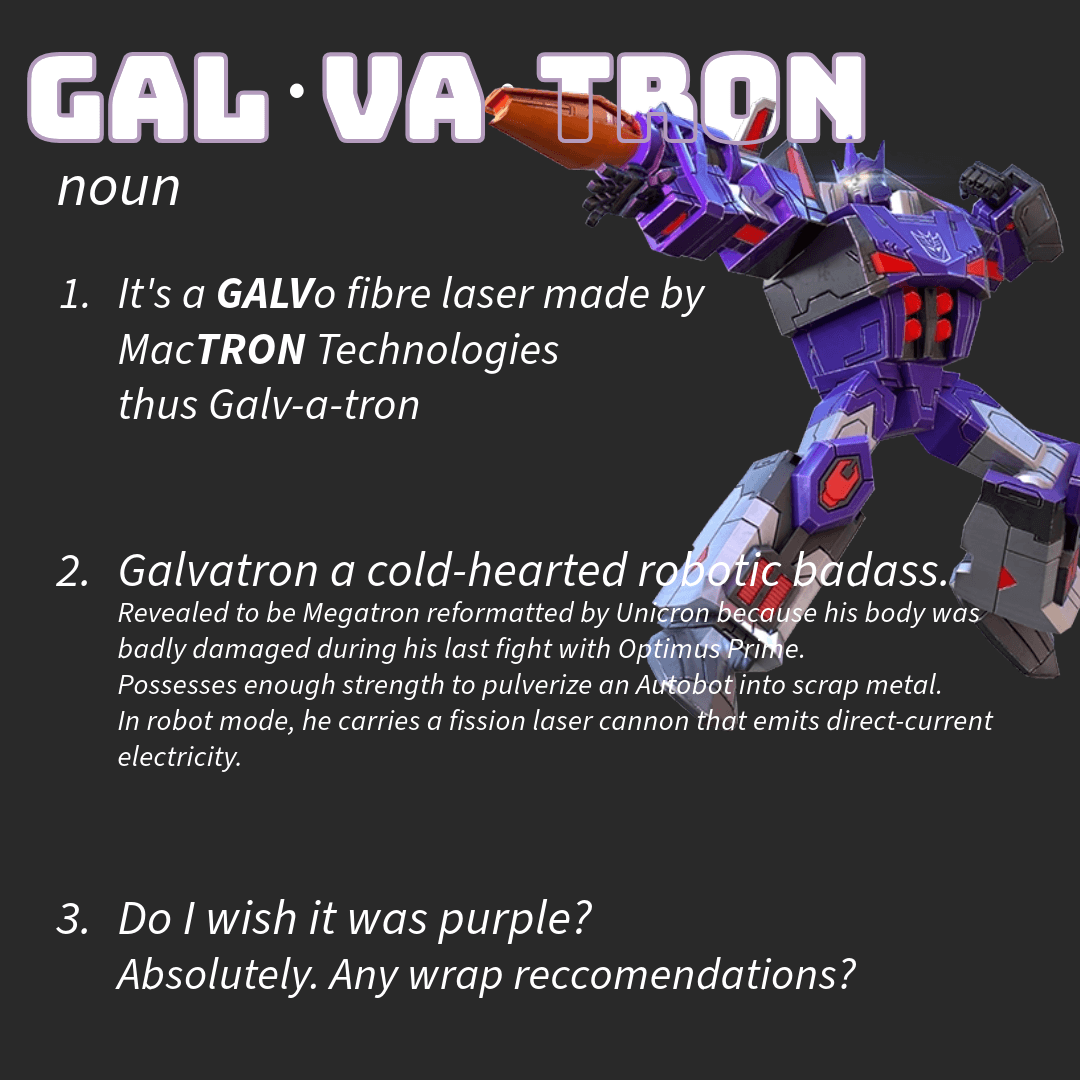

Meet Galv, my fibre laser

Ol' Galv (Galvatron when it's behaving,) is a 50w Galvo JPT fibre laser engraver, made by Mactron Technologies.

I currently run two lens options, the 160mm which gives working diameters of approximately 180mm x 180mm, and a 220mm lens, providing approximately 280mmx280mm depending on the material and depth being engraved.

Y axis height is approximately 500mm.

This laser can engrave a variety of materials, I currently offer engraving for most metals (most commonly steel, ali & brass) some stone and vegetable tanned leathers. At this stage, I do not offer engraving for wood, acrylics, PV/Vegan leather, chrome tanned leather or glass.

What is a fibre laser engraver?

OmTechlaser.com have a great, easy to follow explanation, snippets can be found below, and the full explanation can be found here

In the engraving process, a focused beam of light is sent through a fiber optic cable and used to mark and/or remove the surface of the material.

The galvanometric drive system uses high-speed, motor-driven mirrors to direct the beam through its lenses. As the only moving parts are the mirrors, the laser beam is able to move at high speeds in an easily repeatable way in one or two dimensions.

F-theta lenses are often used in galvanometric scanning systems that are comprised of two mirrors. One mirror controls beam deflection in one direction and the other controls beam direction in the perpendicular direction. The F-theta lens then focuses the laser precisely on the planar surface.

Fiber lasers produce a more concentrated laser beam, so they're great for jobs that require precise, high-contrast marks. Fiber lasers are much faster than CO2 lasers and cause less damage to the surrounding material because they only affect the surface layer. They also take up less space.

CO2 lasers, on the other hand, can be used on a wider variety of materials, including glass, plastic, leather, wood, and stone, among others. CO2 lasers perform better on thicker materials as well. However, you have to be careful when using CO2 lasers on highly reflective metals, since the laser could be reflected back into the machine, which could damage it.